SPLIT AIRCONDITIONER

What is the Difference Between Inverter and Non-Inverter AC

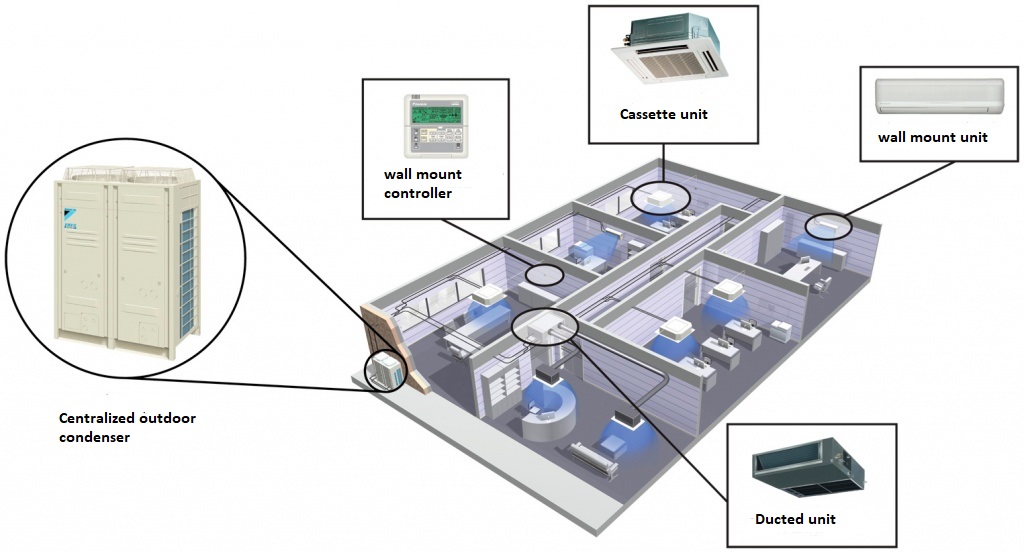

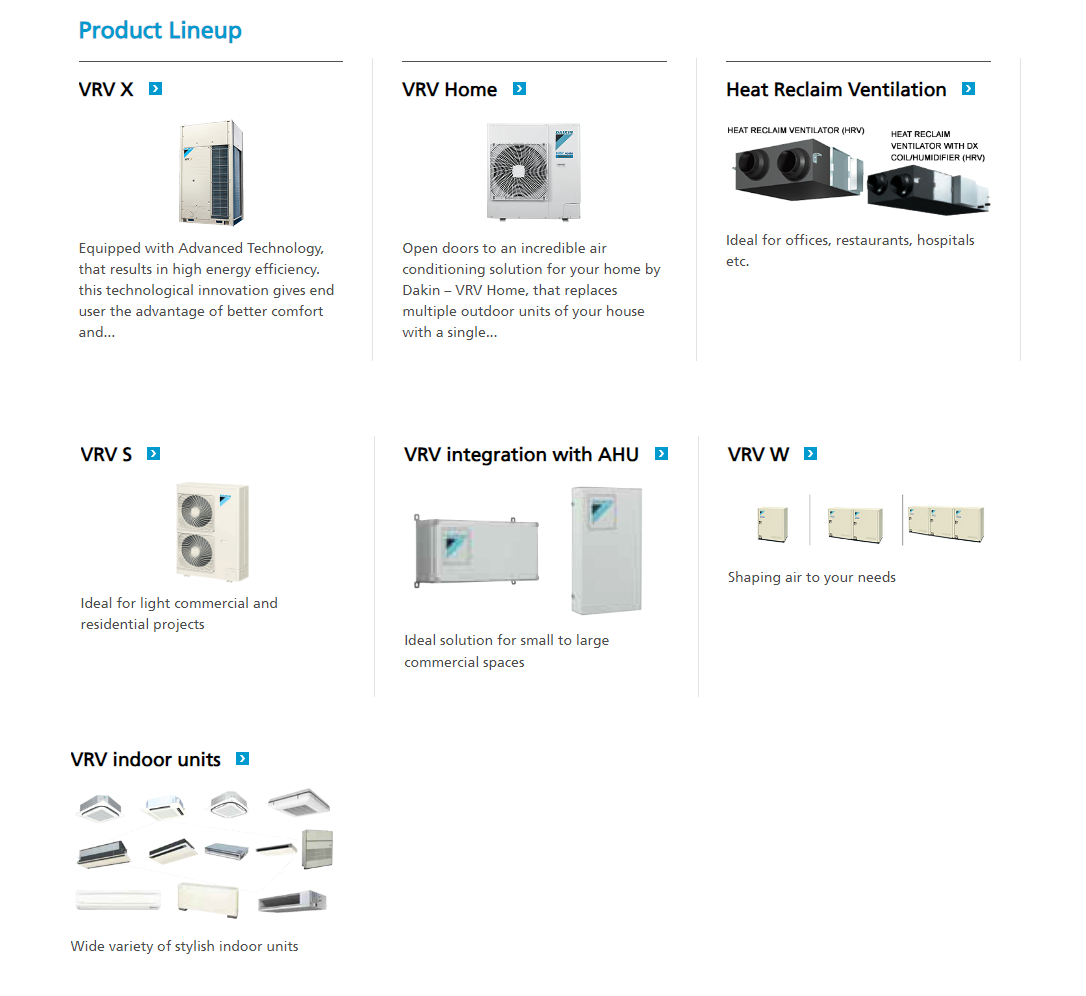

HVAC systems, including Variable Refrigerant Volume (VRV) systems, work to provide heating, cooling, and ventilation to indoor spaces. Here's how a typical VRV system works and some of its benefits:

Working Principle: VRV systems use a single outdoor condensing unit that is connected to multiple indoor fan coil units. The system adjusts the refrigerant flow to each indoor unit based on the heating or cooling needs of that particular zone, which is controlled by individual thermostats. This allows for different zones to be heated or cooled independently, providing greater flexibility and energy efficiency. Benefits: Energy Efficiency: VRV systems are highly efficient due to their ability to modulate the refrigerant flow based on the actual load requirements of each zone, reducing energy consumption compared to traditional systems. Individual Zone Control: With VRV systems, each zone can be controlled independently, allowing for personalized comfort settings in different areas of a building. Space Saving: VRV systems require less space for ductwork compared to traditional HVAC systems, making them suitable for installations in buildings with limited space. Quiet Operation: VRV systems are known for their quiet operation, as the compressor is located outdoors and the indoor units produce minimal noise. Easy Installation and Maintenance: The modular nature of VRV systems allows for easier installation and maintenance compared to traditional systems, which can lead to cost savings over time. Overall, VRV systems offer superior comfort, energy efficiency, and flexibility, making them an ideal choice for commercial spaces like offices and malls.

Floor standing air conditioning systems, also known as floor mounted or vertical air conditioners, are a type of cooling system that is installed on the floor of a room. Here are some key features and benefits of floor standing AC systems:

1. Design: Floor standing AC units are tall and slim, resembling a tower. They are designed to be placed on the floor and are ideal for rooms where wall space is limited or where a more discreet cooling solution is desired. 2. Cooling Capacity: Floor standing AC units are available in various cooling capacities to suit different room sizes and cooling needs. They are suitable for both residential and commercial spaces. 3. Airflow: These units typically have a powerful fan that can distribute cool air evenly throughout the room. Some models may also have adjustable louvers to direct airflow where it is needed most. 4. Installation: Floor standing AC units are relatively easy to install compared to other types of AC systems. They usually require a power outlet and proper ventilation for the exhaust air. 5. Energy Efficiency: Many floor standing AC units are equipped with energy-saving features such as inverter technology, which helps reduce energy consumption and operating costs. 6. Remote Control: Like other AC systems, floor standing units often come with a remote control for convenient operation. Some models may also have additional features such as timers and sleep modes. 7. Quiet Operation: Floor standing AC units are designed to operate quietly, making them suitable for use in bedrooms, living rooms, and other areas where noise levels need to be kept low. Overall, floor standing AC systems are a versatile and effective cooling solution for rooms where traditional wall-mounted or window AC units may not be suitable. They offer powerful cooling, energy efficiency, and easy installation, making them a popular choice for many homes and businesses.

HVAC (Heating, Ventilation, and Air Conditioning) ventilation systems are essential components of building HVAC systems, responsible for maintaining indoor air quality and regulating airflow.

1.Function: HVAC ventilation systems provide a controlled exchange of outdoor air with indoor air, removing contaminants such as odors, moisture, and airborne pollutants. They also help regulate indoor temperature and humidity levels. 2.Types of Ventilation Systems: Natural Ventilation: Relies on natural airflow through windows, doors, and vents to provide fresh air and remove stale air. It is a passive system and may not be suitable for all climates or buildings. Mechanical Ventilation: Uses fans or blowers to circulate air. There are several types of mechanical ventilation systems: Exhaust Ventilation: Uses exhaust fans to remove stale air from the building. It is commonly used in bathrooms and kitchens. Supply Ventilation: Brings outdoor air into the building through a fan or blower, improving indoor air quality. This air may be mixed with the return air from the building to reduce energy costs. Balanced Ventilation: Combines both exhaust and supply ventilation to ensure a balanced airflow, maintaining indoor air quality while minimizing energy loss. Energy Recovery Ventilation (ERV): Uses a heat exchanger to transfer heat and moisture between incoming and outgoing air streams, improving energy efficiency. 3.Components: Ductwork: Ventilation systems use ducts to distribute air throughout the building. Ducts can be made of metal, fiberglass, or other materials. Fans/Blowers: These components are used to move air through the ventilation system. They can be located in various parts of the system, such as in the ductwork or at the exhaust points. Air Filters: Filters are used to remove dust, pollen, and other particles from the air before it is circulated through the building. 4.Benefits: Improved Indoor Air Quality: Ventilation systems help remove pollutants and allergens from indoor air, promoting a healthier indoor environment. Energy Efficiency: Properly designed ventilation systems can help reduce energy costs by ensuring efficient airflow and temperature control. Comfort: By regulating airflow and humidity levels, ventilation systems help maintain a comfortable indoor environment. Compliance: Ventilation systems are often required to meet building codes and standards for indoor air quality.

Ductable air conditioners, also known as ducted air conditioners, are a type of air conditioning system that uses ducts to distribute cooled or heated air throughout a building. Here's how they work and some of their key features:

1. Working Principle:Ductable ACs consist of an indoor unit, typically installed in a ceiling or a hidden location, and an outdoor unit. The indoor unit is connected to a network of ducts that distribute the conditioned air to different rooms or zones in the building. 2. Air Distribution: The cooled or heated air is distributed through vents or diffusers located in the ceiling or walls of each room. The ducts also return the air back to the indoor unit for re-cooling or re-heating. 3. Temperature Control: Ductable ACs usually have a central thermostat that controls the temperature of the air being distributed through the ducts. This allows for consistent and even cooling or heating throughout the building. 4. Benefits: Space Saving: Ductable ACs are ideal for buildings where space is limited, as the indoor unit is typically installed out of sight. Aesthetic Appeal: The vents or diffusers used with ductable ACs are often less obtrusive than wall-mounted units, providing a cleaner look to the interior space. Energy Efficiency: Ductable ACs can be more energy-efficient than other types of AC systems, especially when combined with modern technologies like inverter compressors and variable-speed fans. Quiet Operation: Since the noisy components of the AC system are located outdoors or in a separate mechanical room, ductable ACs can operate more quietly than other types of systems. 5. Applications: Ductable ACs are commonly used in commercial buildings, offices, hotels, and larger residential spaces where central cooling and heating are required. They are also used in buildings where maintaining a consistent and controlled indoor environment is important, such as hospitals, data centers, and laboratories. Overall, ductable air conditioners offer a versatile and efficient cooling and heating solution for buildings of various sizes and applications. They provide consistent comfort, energy efficiency, and aesthetic appeal, making them a popular choice for many HVAC installations.

Ceiling cassette air conditioners, also known as cassette ACs, are a type of air conditioning system that is mounted in the ceiling of a room. Here's how they work and some of their key features:

Working Principle: Ceiling cassette ACs consist of an indoor unit that is mounted in the ceiling, typically in the center of the room. The unit is connected to an outdoor unit via refrigerant lines and electrical wiring. The indoor unit blows cooled or heated air into the room through a set of vents located on the sides of the unit. Air Distribution: Ceiling cassette ACs are designed to provide 360-degree airflow, ensuring even distribution of air throughout the room. This helps maintain a consistent temperature and provides better comfort compared to wall-mounted units. Installation: Ceiling cassette ACs are installed flush with the ceiling, with only the vents visible. This makes them a discreet and aesthetically pleasing option, suitable for modern interior designs. Remote Control: Like other AC systems, ceiling cassette units are typically controlled by a remote control, allowing users to adjust the temperature and fan speed from anywhere in the room. Energy Efficiency: Many ceiling cassette ACs are equipped with energy-saving features, such as inverter technology, which adjusts the compressor speed to match the cooling or heating requirements of the room. This helps reduce energy consumption and operating costs. Applications: Ceiling cassette ACs are commonly used in commercial spaces such as offices, conference rooms, and retail stores, where a discreet and efficient cooling solution is required. They are also used in residential settings, especially in homes with modern interior designs and limited wall space for traditional wall-mounted units. Benefits: Discreet Installation: The flush-mount design of ceiling cassette ACs makes them a discreet and unobtrusive option for cooling or heating a room. Even Air Distribution: The 360-degree airflow of ceiling cassette units ensures that air is distributed evenly throughout the room, providing consistent comfort. Aesthetic Appeal: Ceiling cassette ACs have a sleek and modern look, making them a stylish addition to any room. Overall, ceiling cassette air conditioners offer a versatile and efficient cooling and heating solution for both commercial and residential spaces. They provide even air distribution, energy efficiency, and a discreet installation, making them a popular choice for many HVAC installations.

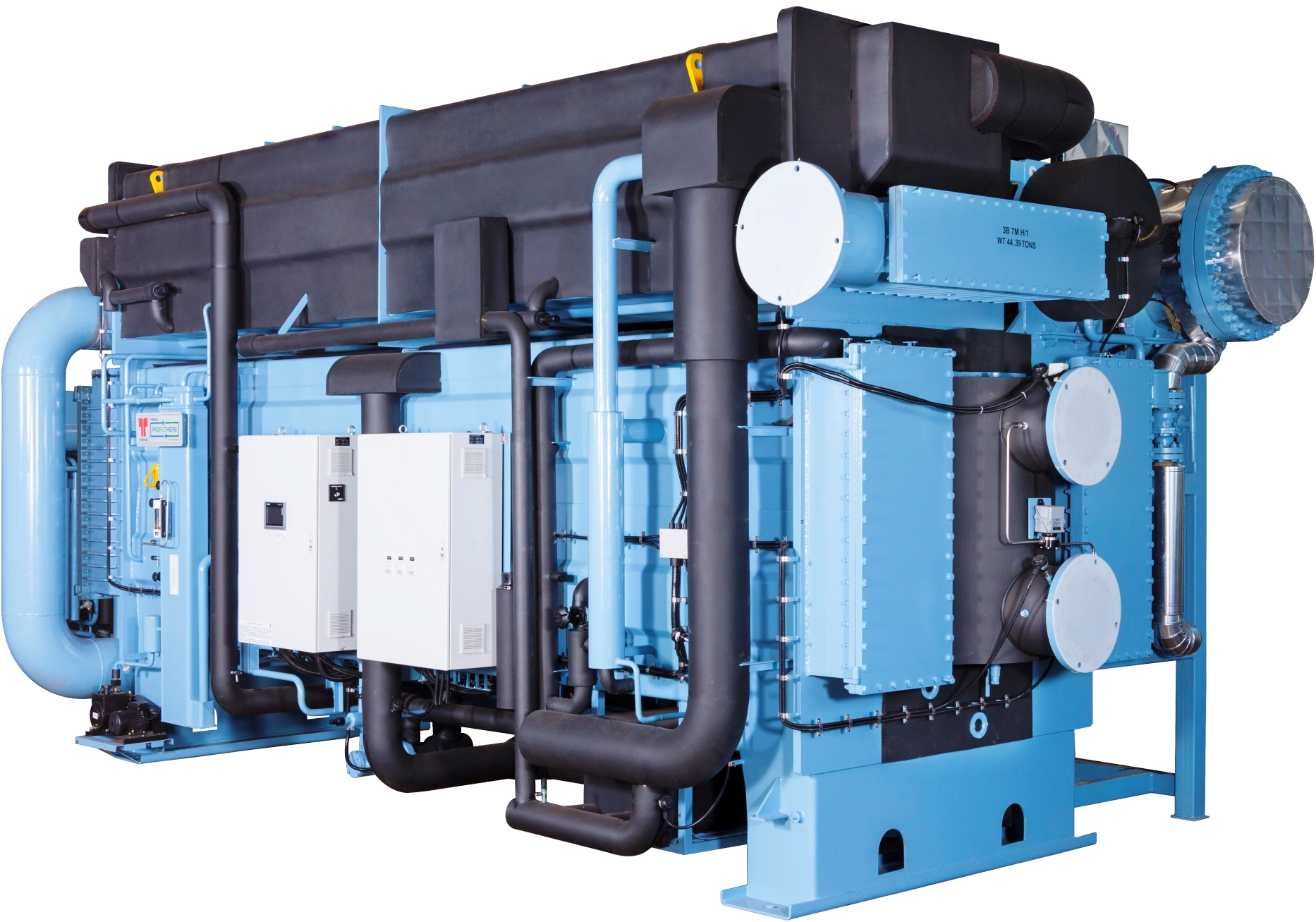

Both chillers and heat pumps are efficient HVAC systems that can provide effective cooling and heating solutions. The choice between a chiller and a heat pump depends on the specific requirements of the application, such as the size of the space, the cooling or heating load, and the availability of a suitable heat source or sink.

Chillers and heat pumps are HVAC systems used for cooling and heating, respectively. They work on the same basic principle but are designed for different purposes. Here's an overview of each: Chiller: Function: A chiller is a machine that removes heat from a liquid, typically water or a water-glycol mixture, to cool a space or process. Chillers are commonly used in commercial and industrial settings to cool large buildings, equipment, or industrial processes. Working Principle: Chillers use a refrigeration cycle to remove heat from the liquid. The liquid is circulated through a system of pipes to absorb heat from the space or process being cooled. The heat is then transferred to the refrigerant in the chiller, which is then expelled to the outside air. Types: There are different types of chillers, including air-cooled chillers, which use air to remove heat from the refrigerant, and water-cooled chillers, which use water for heat removal. Heat Pump: Function: A heat pump is a device that can provide both heating and cooling by transferring heat from one place to another. Heat pumps are commonly used in residential and commercial buildings for space heating and cooling. Working Principle: Heat pumps use a refrigeration cycle similar to that of a chiller but can reverse the flow of refrigerant to provide heating or cooling as needed. In heating mode, the heat pump extracts heat from the outside air, ground, or water source and transfers it indoors. In cooling mode, the process is reversed, and heat is transferred from indoors to outdoors. Types: There are several types of heat pumps, including air-source heat pumps, which extract heat from the outdoor air, and ground-source heat pumps, which extract heat from the ground or a body of water. Chillers and heat pumps come in various types Chiller Types: Air-Cooled Chillers: These chillers use air to remove heat from the refrigerant. They are typically used in smaller applications where water availability or quality is a concern. Water-Cooled Chillers: Water-cooled chillers use water to remove heat from the refrigerant. They are more efficient than air-cooled chillers but require access to a reliable source of water. Absorption Chillers: Absorption chillers use a heat source, such as natural gas or waste heat, to drive the refrigeration cycle. They are often used in large commercial and industrial applications. Centrifugal Chillers: Centrifugal chillers use a rotating compressor to compress the refrigerant. They are highly efficient and are often used in large commercial buildings and industrial applications. Heat Pump Types: Air-Source Heat Pumps: These heat pumps extract heat from the outdoor air and transfer it indoors for heating. They are commonly used in residential and commercial buildings. Ground-Source Heat Pumps (Geothermal Heat Pumps): Ground-source heat pumps extract heat from the ground or a body of water and transfer it indoors for heating. They are more efficient than air-source heat pumps but are more expensive to install. Water-Source Heat Pumps: Water-source heat pumps extract heat from a water source, such as a lake or river, and transfer it indoors for heating. They are commonly used in commercial and industrial applications. Absorption Heat Pumps: Absorption heat pumps use a heat source, such as natural gas or waste heat, to drive the refrigeration cycle and provide heating. They are often used in large commercial and industrial applications.

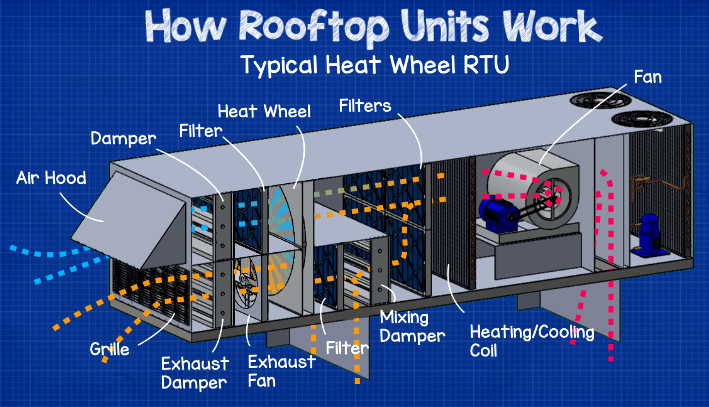

rooftop units offer a convenient and efficient HVAC solution for commercial buildings, providing heating, cooling, and ventilation in a single package. Their location on the roof also helps minimize noise and frees up space inside the building for other uses.

Location and Design: RTUs are installed on the roof of a building, saving space inside. They are housed in a weatherproof enclosure and contain all the necessary components for HVAC operation, including the compressor, condenser, evaporator, fans, and controls. Air Intake and Exhaust: RTUs draw in outside air through intake vents and then condition it using the HVAC components. The conditioned air is distributed through ductwork to different areas of the building. The exhaust air is expelled back outside. Heating and Cooling: RTUs can provide both heating and cooling. In cooling mode, the refrigerant absorbs heat from the indoor air, which is then expelled outside. In heating mode, the process is reversed, with the refrigerant absorbing heat from the outside air (or from a heat source such as a gas burner) and transferring it indoors. Ventilation: RTUs also handle ventilation by bringing in a controlled amount of fresh air from outside to maintain indoor air quality. This air is typically mixed with the conditioned air before being distributed throughout the building. Controls and Efficiency: RTUs are often equipped with sophisticated controls that allow for precise temperature and humidity control. They can also be highly efficient, with features such as variable-speed fans and energy recovery systems to reduce energy consumption.